What is the primary difference between disinfection and sterilization?

Disinfection kills all microorganisms, while sterilization kills most

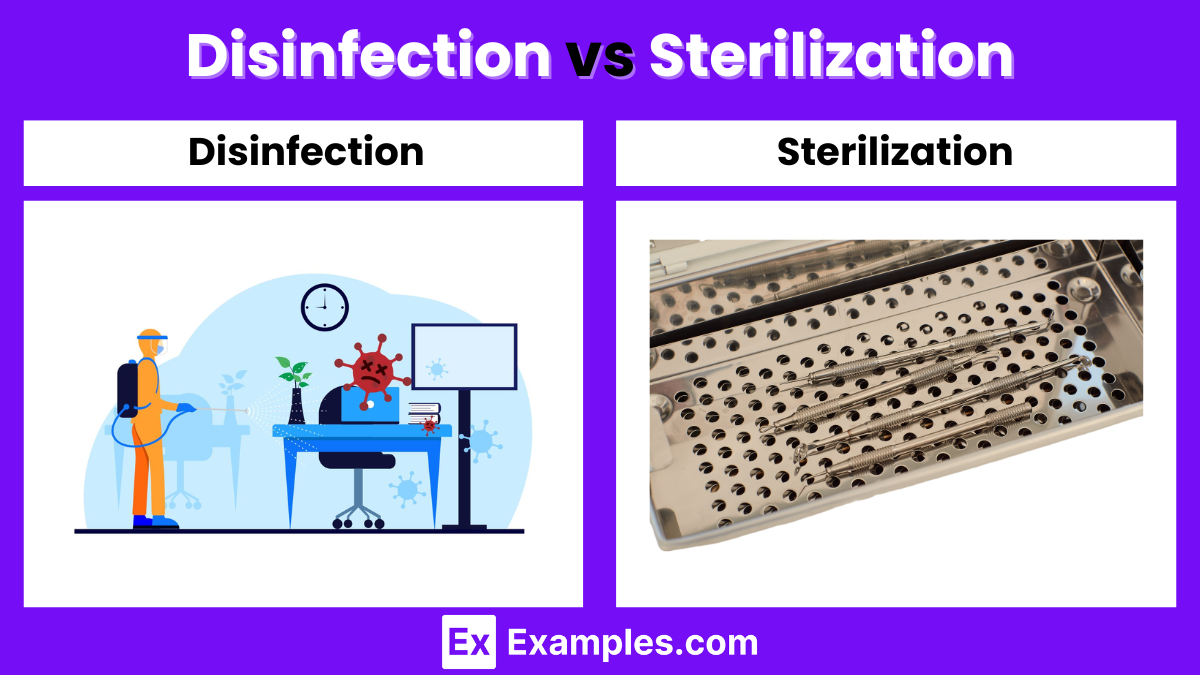

Disinfection kills most microorganisms, while sterilization kills all

Disinfection uses heat, while sterilization uses chemicals

Disinfection is used for medical instruments, while sterilization is used for surfaces