As per the popular quote, you have to give credit where credit is due. This means that the effort, time, knowledge, skills, and talent, etc. that people exert to complete certain tasks and activities should be given the right credit or merit.

In this sense, an appreciation certificate is given to people, mostly sanctioned to attend or carry specific tasks, who have successfully completed certain activities or actions. It is also given to people who have displayed exemplary performance within a certain period of time. This is to validate and recognize the effort and time they have devoted to helping in the completion of an event, activity, action, and so on.

Elements of an Appreciation Certificate

Should you be tasked to make an appreciation certificate, here are the essential elements that you should include:

Text Elements

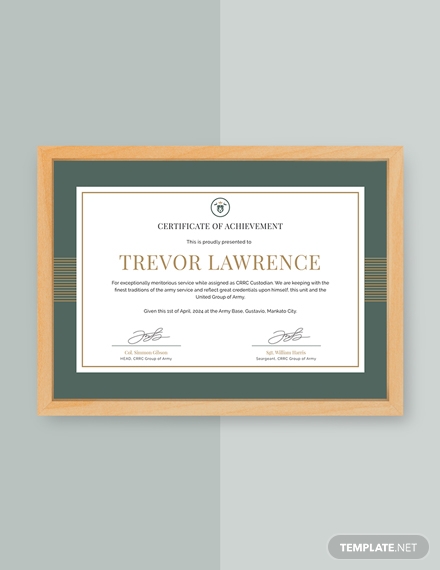

1. Title: The title should be indicated at the center of the topmost part of certificate template. It is essentially the main headline that reflects what type of certificate it is. In this case, the title of the certificate should be Appreciation Certificate or Certificate of Appreciation written in big and bold font/s.

2. Presentation Line: The presentation line is a direct statement that basically introduces the award or certificate to the recipient. The most commonly used presentation lines are as follows: as awarded to, is hereby presented to, This certificate is presented on [date] by [from] to [name of recipient].

3. Recipient Name: The name of the recipient should immediately follow the presentation line. It is important to indicate the complete name of the recipient to certify that it is actually intended for him or her, and so that illegal duplication can be avoided. The name should be written in bold letters so that it can be easily readable.

4. Description: A simple statement explaining why the certificate was given should be indicated below the name of the recipient. It should outline the essential characteristics or performance that the recipient has displayed to merit the certificate. Furthermore, details such as the name of the award-giving body, the date when the award was given, where it was held, etc. should also be included.

5. Signature Line: After the details have been provided, there should be a designated area below for the authorized signature/s. The name and title or position of the authorized signer should be indicated in the signature line.

Design Elements

1. Border: It is best to use or include a border that fits the overall aesthetics of the certificate. The border will determine the boundaries where you should only put the details in your certificate. Moreover, it helps ensure that the contents are all balanced and aligned.

2. Logo: For branding and identification purposes, it is best to include the company or business logo on the certificate. This is usually indicated on the topmost part of the certificate adjacent to the title.

3. Seal: Aside from the logo, a seal can also be included to certify the legitimacy of the certificate. For example, in a student award certificate, the school’s official seal is included in the certificate to provide further proof that the authorized giving body has issued it.

4. Lines: Like a fill-in-the-blank form, you can provide lines to for the name, date, and signature. If this is the case, information for such sections can either be typed or handwritten.

30+ Appreciation Certificate Templates

Modern Appreciation Certificate Example

Appreciation Certificate Example for Employee

Appreciation Certificate Example for Employee

Certificate of Appreciation for Training Example

Certificate of Appreciation for Student Example

Graduation Appreciation Example Certificate

Appreciation Certificate for Employee Merit

Creative Employee Appreciation Example Certificate

Simple Volunteer Appreciation Example Certificate

Appreciation Certificate of Skating Template

Outstanding Student Appreciation Certificate Template

Funny Appreciation Certificate Template

Appreciation Certificate Template

Appreciation Certificate Template

Volunteer Appreciation Certificate

Certificate of Appreciation for Training

Employee Appreciation Certificate

Sports Appreciation Certificate

Sponsorship Appreciation Certificate

Formal Certificate of Appreciation

Girl Scout Certificate of Appreciation

Certificate of Appreciation for Student

Graduation Appreciation Certificate

Volleyball Appreciation Certificate

Certificate of Appreciation for Teacher

Employee Certificate of Appreciation

Army Certificate of Appreciation

Church Certificate of Appreciation

Retirement Certificate Template

Military Certificate of Appreciation

Soccer Award Certificate

How to Create an Appreciation Certificate

To help you create an effective appreciation certificate in Microsoft Word, you may refer to the short guide provided below:

1. Open new document: After launching the software, quite a few options will appear; click the blank document option. Choosing this option will give a you a complete blank page where you can start creating the certificate from scratch.

2. Search for templates (optional): If you do not want to start from scratch, you can also use an appreciation certificate template where you can easily fill in the required information. To do this, instead of choosing a blank document click the search bar and type out the exact template you are looking for.

3. Choose background color: If you want to use a background color for the certificate, you can easily do that by going to the Design tab. Then, click the Page Color option so that a variety of color options for the background will appear.

4. Insert image/s: You can easily insert the logo and necessary images or illustrations in your certificate. Go to the Insert tab, then choose the Picture option. After that, the Insert Picture dialogue box will appear where you can choose the desired image, then click Insert to add it to the page. You may also see Participation Certificate Examples & Templates.

5. Change picture layout: To ensure that the image you have inserted is of the right size and can be moved to where its supposed to be, you need to change its layout. To do this, click the Layout Options button lingering near on the upper right hand of the image. There, a variety of options will appear; click what layout you want your image to be when immersed with the texts.

6. Insert text boxes: After placing the image on the certificate, proceed to insert text boxes where you can easily type out your content. Go to the Insert tab and click the Text Box option. A drop-down will appear, choose the draw text box. You can draw the size of the text box that you will need.

7. Type out texts: After that, you can immediately begin typing out the information for the certificate within the text box. You can insert as much text boxes that you need in order to provide sufficient information.

8. Proofread and edit: Make sure there are no spelling errors, grammatical mistakes, inaccurate information, and so on in the certificate. Proofread and edit the certificate before printing. Read on about Achievement Certificate Examples & Templates.

Tips in Designing an Appreciation Certificate

Here are some useful tips in creating an appreciation certificate:

1. Choose good quality paper stock: The quality of the paper stock you use will affect the final output of your certificate. Choosing a low quality and thin paper will change the color of the ink and will definitely feel flimsy and unprofessional. On the other hand, thick and heavier paper stock is more substantial.

2. Choose an appropriate color scheme: You need to make sure that the certificate will appear more well-put and professional; therefore, you need to choose colors that exude professionalism like lacks, grays, and blues on white paper.

3. Maintain a neat layout: Since you only a small space to work in, make sure that the overall layout of your certificate is neat and clean. There should be a balance between the contents and the white space to ensure that it is not messy to look at.

4. Avoid using too many font styles: You can use a variety of fonts to emphasize certain words in the certificate; however, it is best to avoid using more than three font styles. Read about Attendance Certificate Examples & Templates.