HACCP Principles & Plans Examples to Download

Are you an owner of a food business? The HACCP system should be implemented in your company because it is an essential part of your quality assurance program. It is the cornerstone of your company’s product safety system and is compatible with the overall quality assurance program. However, to put this system into action, you’ll need to gain system knowledge and understanding, as well as commitment, planning, and resources. As a result, we’ve included some valuable tips in this article to help you out. We also have some templates available for free download.

4+ HACCP Principles & Plans Examples

1. HACCP Principles Example

2. HACCP Plans Example

3. HACCP Principles in Meat Plants

4. Food Safety HACCP Principles & Plans

5. HACCP Principles & Plans

What Is The Importance Of a HACCP?

HACCP is significant because it prioritizes and monitors potential risks in the production of foodstuffs. The industry can assure consumers that its products are as safe as good research and technology can control significant food hazards, such as microbiological, chemical, and physical contaminants.

How To Create a HACCP Plan?

Similar to structure and design for projects commonly utilized in different firms, implementing HACCP principles in conjunction with a project plan requires a list of steps supplemented by resources and provisions created by research and testing for technical process development, critical inspection points, and other critical limitations. If you plan to be aware of things you need to work on, you can run a successful business. We recommend that you follow the following steps in this section:

1. Make a policy and set goals.

Do you need to reduce customer complaints from the previous year? Do you wish to conduct pre-employment food safety induction training for new employees? Consider the goals and objectives established by your food business in producing and delivering safe and nutritious food to your customers.

2. Form a team and appoint a team coordinator.

A HACCP team coordinator should possess strong communication skills and relate to staff at all levels and establish trust. While the team should include familiar with all aspects of the manufacturing process, it should also have specialists in specific fields such as microbiology or engineering.

3. Create a flow diagram with your team.

Create a list of the target food products, label each one, and include raw materials and ingredients. It would help if you created a flow diagram to depict the process. Create unique flow diagrams for each product that detail the critical control points and their associated types for specific hazards.

4. Perform a risk assessment and identify critical control points.

Examine the potential hazards that could arise during the manufacturing process. Please keep track of the hazard analysis and risk categories for the target products, their ingredients, and the dangers throughout the product food chain. After that, write down the necessary limit monitoring procedures and the monitoring frequency and the names of the people in charge of specific monitoring activities. Include deviation procedures for each, determining what action should be taken if monitoring indicates something is out of control.

FAQS

What is the most crucial aspect of implementing HACCP?

A preventive control system for the safety of food products is the most important part of HACCP. End product inspection cannot carry out the prevention of hazards. The best way is to monitor the manufacturing process with HACCP.

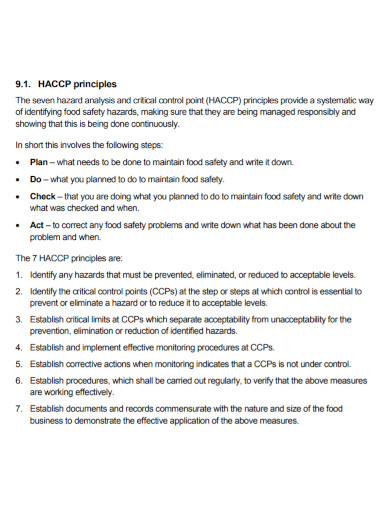

What are the seven HACCP principles?

Danger analysis, CCP detection, vital limit setting, control procedures, remedial measures, verification procedures, and record-keeping and recording are the seven HACCP concepts.

What is the flow chart for HACCP?

A HACCP flow chart depicts the food operation’s process flow from raw materials to finished product. Typically, a HACCP flow chart is created by a group referred to as the HACCP Team or Food Safety Team.

Throughout your food business, the proper application of the HACCP system is essential to control any food area or point that could contribute to a harmful event, such as contaminants, pathogens, objects, chemicals, raw materials, a process, and more. The development of a systematic HACCP Plan is helpful to improve your food products’ safety and good quality. To begin, download now in this article our plan template!