25+ Maintenance Checklist Examples to Download

A checklist template is a tool that typically lists items, tasks, or points to be considered or acted upon. A checklist, in most cases, is used to aid the human mind on things that are a bit too much for us to handle or remember. A checklist is often used to ensure that the task and the things for consideration were completed, without missing a thing or two. Here, we are going to discuss a few points about maintenance checklists.

A maintenance checklist is an essential tool that helps individuals and businesses ensure their equipment and systems operate efficiently and safely. By providing a structured approach to regular inspections and upkeep, this checklist prevents unexpected breakdowns and costly repairs, extending the lifespan of assets and promoting a seamless operational flow. Ideal for various settings, including homes, factories, and offices, a well-crafted maintenance checklist is the backbone of proactive management and reliability

What is Maintenance Checklist?

Maintenance Checklist Format

Maintenance Checklist Example

Maintenance Checklist Examples

Maintenance Checklist Samples

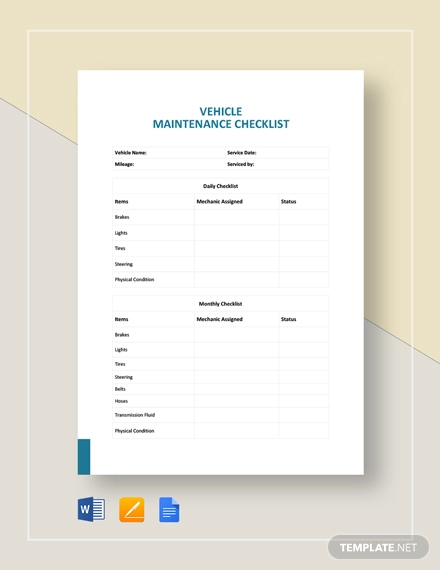

Vehicle Maintenance Checklist Example

Are you on the lookout for a Cleaning Inspection Checklist? Then, checkout this template in order to keep track of your needs and requirements for your cleaning inspection work. Get your cleaning work organized with this template. You can edit and customize this template in any way you want. Download now!

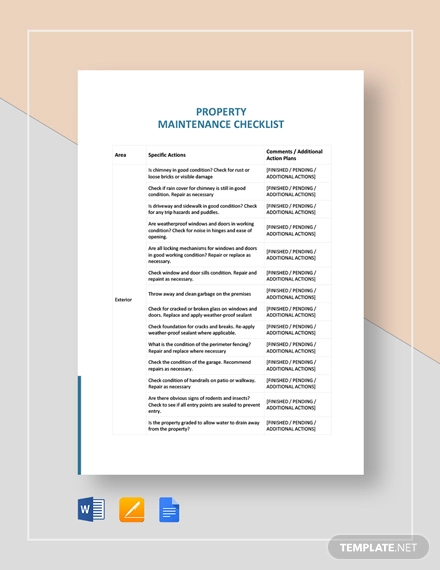

Property Maintenance Checklist

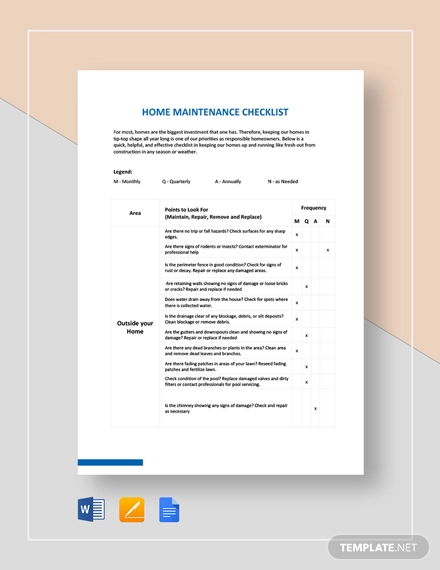

Home Maintenance Checklist

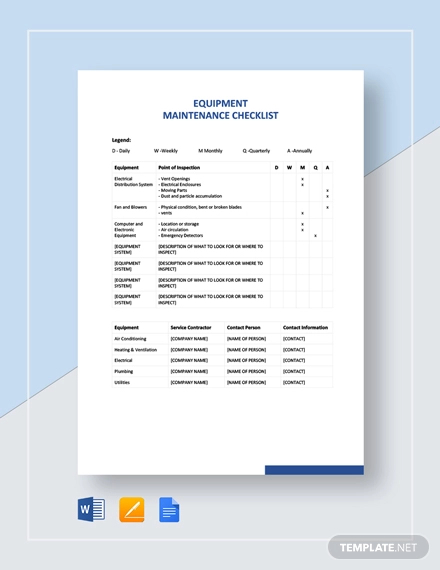

Equipment Maintenance Checklist

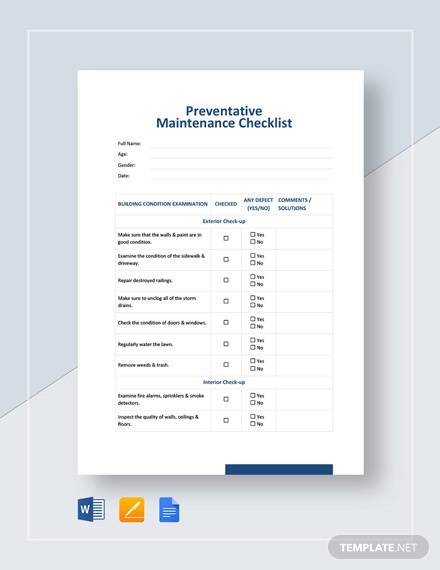

Preventative Maintenance Checklist

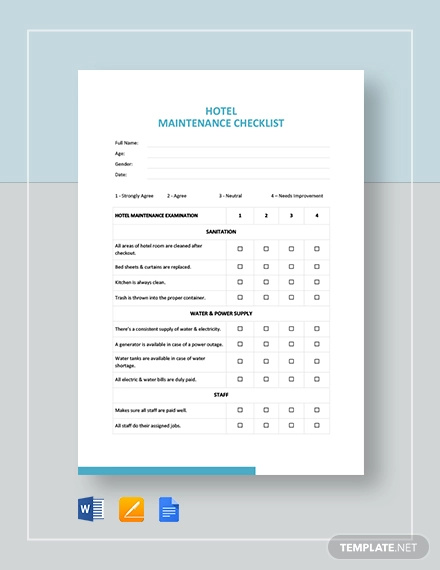

Hotel Maintenance Checklist

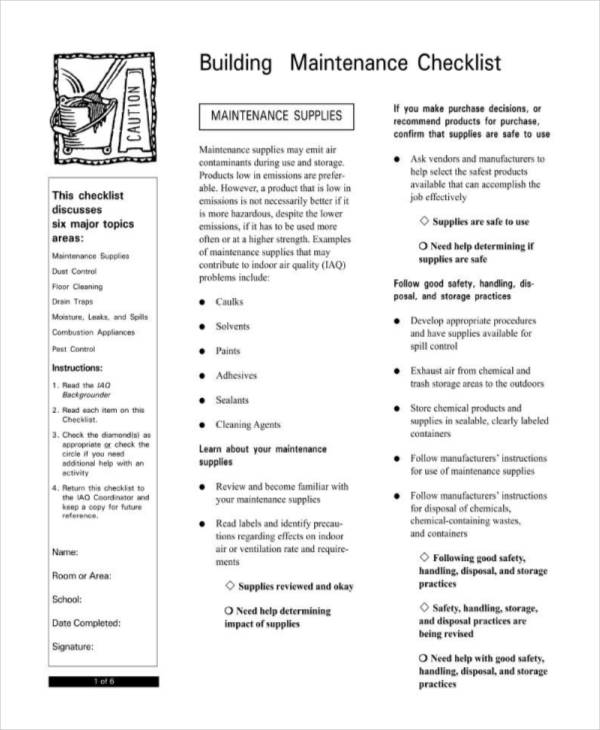

Building Maintenance Checklist

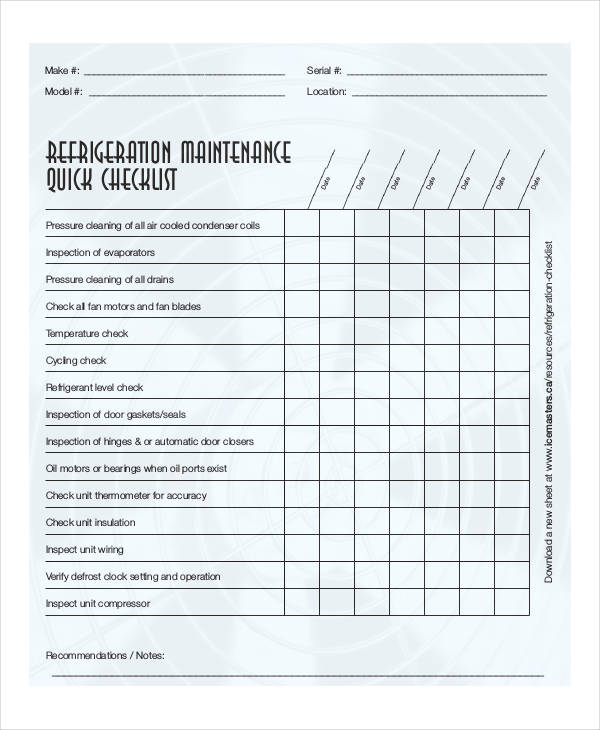

Refrigerator Maintenance Checklist Example

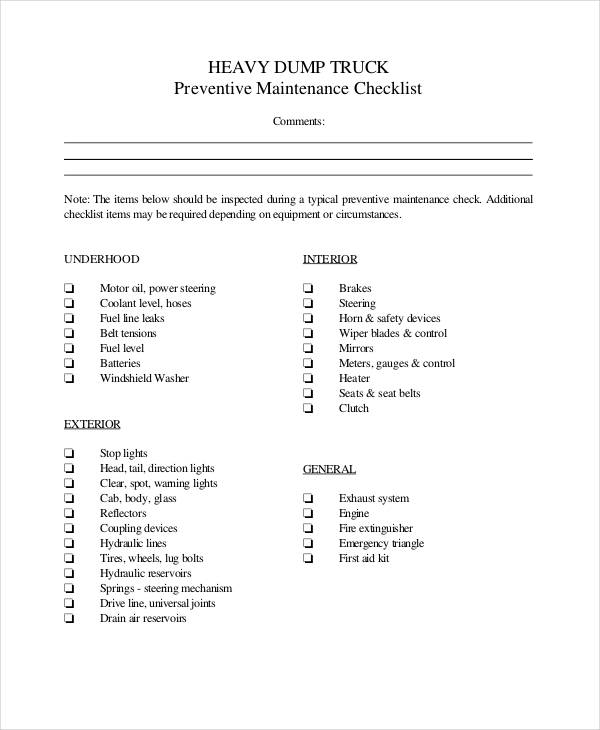

Truck Maintenance Checklist

Importance of a Maintenance Checklist

Tips for Creating a Maintenance Checklist

Writing a maintenance checklist is as critical as conducting the maintenance checklist itself. Thus, it is important for someone writing a maintenance checklist to know the basics of writing a maintenance checklist, or at least, a checklist in PDF. Here are a few tips you can follow to make your own maintenance checklist:

- Know the importance of creating a maintenance checklist: You can write this and put it at the top.

- Carefully consider the items to be included in the checklist: For a maintenance checklist, consider the items which need to be checked.

- List down the processes needed for a successful maintenance check: Some maintenance officers prefer reviewing the processes from time to time, so it would be better than not to include a few instructions.

- Write a detailed description for each item: You might want to write a description for a few items to be checked for easy identification.

- Input the details in an organized manner: Organize your checklist so the maintenance officer won’t have a hard time finding the items.

- Leave a blank for the remarks of the maintenance officer: Maintenance officers may find a few observations which need to be noted and might need a space for such remarks.

- Add a few details and finishing touches for your checklist: Should you find a few details to add to your checklist, you are free to add them to your checklist.