10+ Spec Sheet Examples to Download

With people showing off their outfits of the day on social media, spec sheets are more important than ever. And not just for the fashion industry, the document’s importance is now twice as important in the interior design industry, as well. Whatever type of designer you are, you know very well how crucial it is to provide your customers with the measurements, patterns, or other technical details of your products. Doing so allows them to have ready-made decision criteria on which shirt, jacket, pants, dress, jeans, hoodie, or construction furniture to get to satisfy their individual needs. If you’re looking for examples and know-how about spec sheets, you’re in the right place! Check them out below!

10+ Spec Sheet Examples

1. Spec Sheet Template

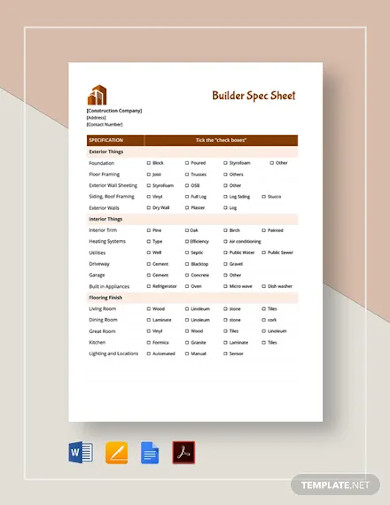

2. Builder Spec Sheet Template

What Is a Spec Sheet?

A spec sheet is a thorough list of a certain product’s characteristics, such as its measurements, functions, and the special features that distinguish it from the others. One of its benefits in the fashion industry is that it helps lessen the likeliness of last-minute changes while providing better control over the garments’ quality. As for the construction industry, it contributes greatly to the building information modeling (BIM) process, giving insights to construction professionals in designing and managing buildings and infrastructures digitally. Note that this type of sheet is not limited to these industries but all business lines that manufacture and utilize products.

Types of Specs in Construction

We all know that a construction project is a complex undertaking. Because of this, construction firms categorize the specifications that come with it to make things simpler. These specifications have three categories, which include the following:

1. Performance Specifications – This type of construction specification details the operational prerequisites of certain machinery.

2. Prescriptive Specifications – In this type of construction specification, the firm explains why the contractor chooses to use a certain material. At the same time, it elaborates on the installation process of the said materials.

3. Proprietary Specifications – This construction specification refers to the document that details a single product type for any installation.

How To Create a Spec Sheet

Spec sheets do not follow a specific format. This means that the presentations of any product knowledge rely heavily on the type of product, as well as the features that you want to disseminate to the consumers or users. Nonetheless, we provide you our outline of steps and insights in creating one, so you won’t have to do it right from scratch.

1. Provide Basic Details

Start your spec sheet by providing the basic details of the subject product. This has to contain the product’s name, product line, and the complete components or ingredients of the product.

2. Set Product Description

After providing the basic details, set the subject product’s description. This will provide the manufacturers and customers the problem statement. Moreover, this section will explain how the product can resolve the enumerated problems. Most of the time, manufacturers create product descriptions to inform customers interestingly why they have to purchase the product.

3. Describe Physical Features

Once you have set out the product description, you can describe the subject product’s physical features. For you to do this, you have to look into its colors and dimensions, such as its thickness, length, width, and height. Also, you have to bear in mind that you have to use the Pantone Color Matching System codes for easier identification.

4. Enumerate Functionalities

Don’t forget to enumerate how the product works. Some products, like appliances, have to or more functions. In such cases, you have to make a list of it all with their corresponding solution. For example, some people use blenders to make milkshakes, while others use them to grind fruits. Either way makes it more convenient for the people to prepare delicious refreshments.

5. Special Features

Every product must have a unique feature that differentiates it favorably to other products of the same kind. Good examples of this are sports watches’ water resistance feature and mobile phones’ shock resistance. Providing these special features does not just establish your product knowledge level but also helps in the execution of your product marketing strategy.

6. Compliance

You must also include in your spec sheet a summary of your compliance strategic plan, specifically the compliance report on your products. But since spec sheets are mostly one to two pages only, you can shorten this section by mentioning your recognitions. These may take the form of ISO, FDA, CE marking, and other certificates that can prove your product’s compliance with the standards.

7. Define Terminologies

One of the spec sheets’ audiences is the customers. However, not all of them are savvy enough to understand every jargon that a technical document such as this uses a lot. For this very reason, you have to provide a section that clearly defines every jargon’s simple equivalent meaning.

FAQs:

Who creates spec sheets?

It is the company’s product designers who create a spec sheet. After doing so, they send the outputs to factories as a guide for the production process.

What are the different types of specifications?

According to John Spacey’s article for Simplicable, there are eight types of specifications. They include requirements, design, material, standard, interface, test, performance, and quality specifications.

What is a tech pack?

A tech pack acts as a diagram of your production plan that consists of technical drawings and patterns. Spec Sheets, which detail the essential information of a certain product, is a part of the tech pack.

Renowned American magnate Henry Ross Perot once said, “Business is not just doing deals; Business is having great products, doing great engineering, and providing tremendous services to customers. Finally, Business is a cobweb of human relationships.” The product of a company is one of its many pillars. And because of that fact, companies have to produce them in the best quality as much as possible. To guide them and provide customers with a breakdown of its components, they must produce a spec sheet, first and foremost. It goes without saying that such a document is very important for businesses.