10+ Warehouse Inventory Examples to Download

Without a fully functional warehouse, a business could only do so much. Why? You might want to ask. The supply chain is the lifeblood of the business. Without efficiency in this area, it will be difficult to expand the business. And Warehouses? They are the lungs that keep your products. That’s why an efficient warehouse not only helps the business but also allows it to grow. Do you know what the best way to improve its efficiency? Simple. Use warehouse documents such as these warehouse inventory samples we have. These will surely keep your business afloat. However, we’re not done yet. We also provided an excellent guide below for anyone interested. Check them out now.

10+ Warehouse Inventory Examples

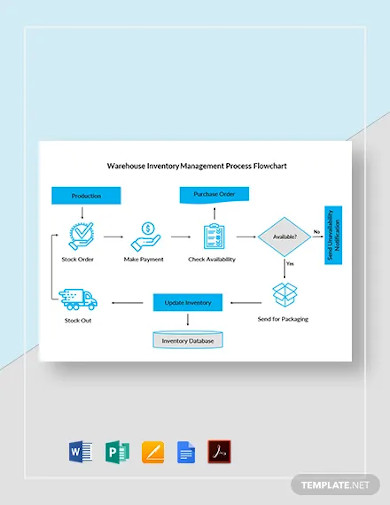

1. Warehouse Inventory Management Process Flowchart Template

2. Inventory Warehouse Management

3. Company Warehouse Inventory

4. Warehousing and Inventory Management

5. International Warehouse Inventory

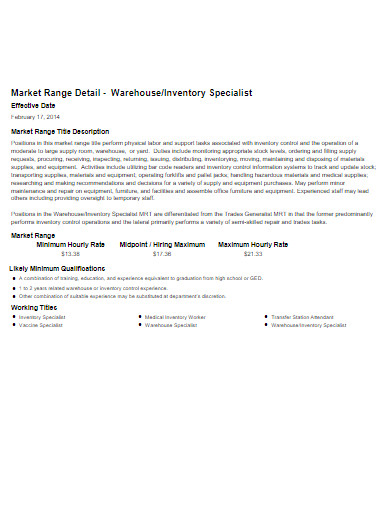

6. Warehouse Inventory Specialist

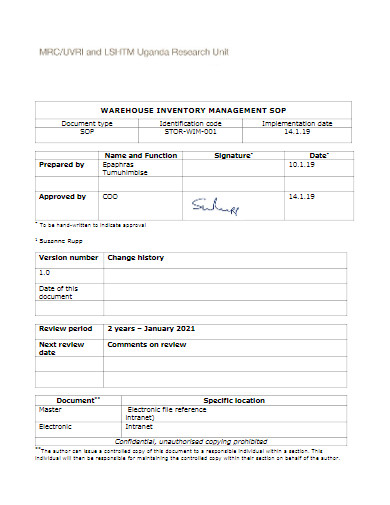

7. Warehouse Inventory Example

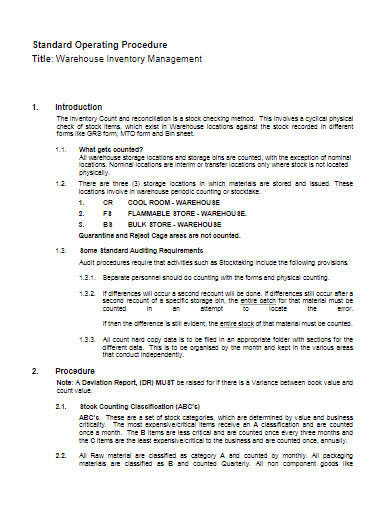

8. Warehouse Inventory Management Template

9. Sample Warehouse Inventory Management

10. Cloud-based Warehouse Inventory

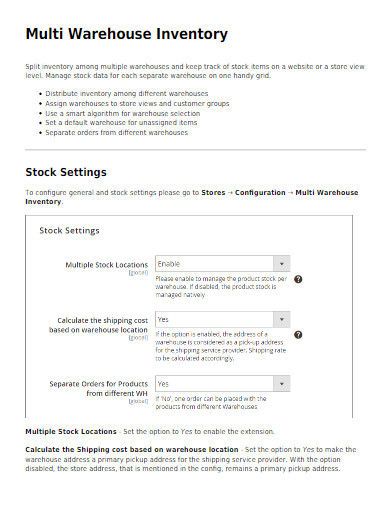

11. Multi Warehouse Inventory

What is a Warehouse Inventory?

A warehouse inventory sheet is a document that the people from the logistics department uses. These templates are good for warehouse personnel to ensure that all the items, both inbound and outbound, are fully accounted for. In this way, you ensure that your business won’t lose items at all.

What are the four types of inventory?

Generally, all items in a company’s warehouse are assets of the company. These things may include products, parts, and other items. However, one of the best ways to segregate them is by applying the four types of inventory. The four types of inventory are:

-

Raw Materials

These items are unprocessed items that the warehouse keeps for processing. Although these items are less costly than the products themselves, they are important and guarded properly.

-

Work In Progress Items

The WIP Items are raw materials that already went through some processes. However, these still lacking some of the steps necessary to consider them shippable products. So, you can expect that these items will be gone sooner or later.

-

Finished Goods

These items are the finished products that went through all the processes. You may only see a glimmer of its raw materials as the whole process refined it. Nonetheless, these items are hot, so make sure that these will be positioned near the loading area, so you can also improve the loading efficiency.

-

MRO

MRO or Maintenance, Repair, and Overhaul are items that your company has for service. These items should generally be placed on a different spot as the individuals who work on these are different from your production team. Depending on the type of product your company has, these items may become hot or not. Electronics, for example, are hot items as owners of these things need fast repairs.

How to Create a Warehouse Inventory?

Warehouse Management is not an easy thing. You need to understand how the whole warehouse works and always be ready to move things. Some of these warehouse managers even use technology like drone and RFID to help them work more efficiently. Nonetheless, a warehouse inventory is quite on the simple scale that even admin assistants can do them.

Step 1: Create a Format

It all starts with a format. If you’re using Microsoft Excel or Google Spreadsheets, it’s going to be easy for you. It’s going to be simple because these programs are useful for doing these things. Some even have a built-in format that you can edit to suit your needs. So you should start creating the format first.

Step 2: Create Group Boxes

If your warehouse has different stockpiles for things that separate the four types of items, then you’re in luck. The easiest way for you to do this is to group the items by stockpile in your inventory. In this way, the checklist you will be adding in the boxes will be for the specific stockpile. This also works with racking shelves if you’re using those. Just do the same principle.

Step 3: Include a Detailed Checklist

As mentioned earlier, you can then use the same groups as checklists to ensure all the items inside the group are all accounted for. However, make sure that your checklists are as detailed as possible. If you can, you should indicate it’s previous numbers within the same line, so people can easily check the inventory.

Step 4: Take Note of Hot Stuff

Hot items are those that come into your warehouse and then disappear as fast as possible. These items may include consumables, finished products, and serviced items. When it comes to these items, make sure that you indicate them well within the group as they can destroy your team’s rhythm if done wrongly. If possible, make sure that you’re using a different paper or document for these things inventory.

FAQs

What is warehousing and inventory management?

Warehousing and inventory management are two separate systems that seek to develop a warehouse’s efficiency. It also guarantees proper inventory of the warehouse, which in return boosts the supply chain.

What is the difference between stock and inventory?

Although these two things are connected, stocking is still different from inventory when it comes to nature. Stock is the storage of items for sale, while inventory encompasses both finished products, work in progress, and raw materials.

Is inventory an asset?

Yes, inventory part of what we cal current asset. They are placed in such a position because they have a monetary value that’s deliverable within the year.

If your company has a flow chart of the supply chain, you know that your warehouse controls much power within the logistics area. So strive never to forget your importance to the whole company and do your job well. You’re an icon!