Warehouse Action Plan Examples to Download to Download

Have you ever gone inside a warehouse before? If you have, you would notice there are a lot of boxes being stored side by side. You may also think of how dangerous Anyone who has ever worked in warehouses can tell you that this kind of job has its own risks and hazards. That working in a job like this that involves a lot of lifting boxes and other items would need a lot of thinking over and a lot of planning. To simply put, any kind of job that may present a lot of hazards may they be health hazards, physical hazards or that could cause pain to an employee or to someone else visiting the site is a good enough reason to plan out what should be done to avoid these kinds of problems from happening. When you plan out a way to lessen the problems that employees or anyone who may be working or visiting the warehouse, you would want to consider writing a warehouse action plan.

3+ Warehouse Action Plan Examples

1. Warehouse Action Plan Template

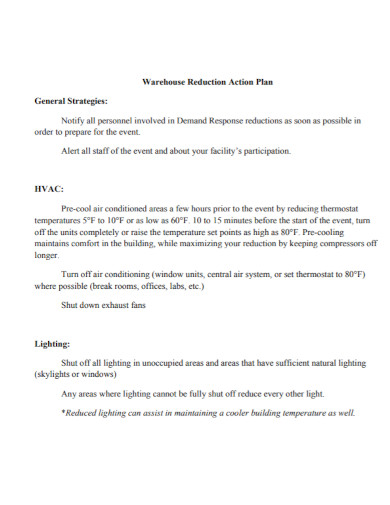

2. Warehouse Reduction Action Plan

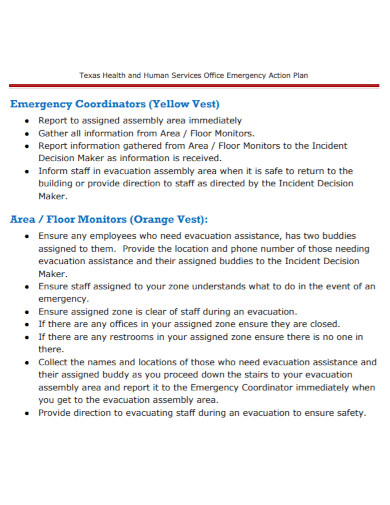

3. Technology Warehouse Action Plan

4. Standard Warehouse Action Plan

What Is a Warehouse Action Plan?

What is a warehouse action plan and what purpose does it have to write one? An action plan is a series of outlined strategies that a person follows to avoid any issues, hazards, risks or problems that go with the job. A warehouse action plan is a kind of action plan that a person composes to outline the step by step ideas or strategies that could benefit the people working in warehouses. As a lot of risks and hazards are found in a type of job such as handling warehouse items, making an action plan to avoid the problems is the most realistic solution. In addition to that, a warehouse action plan consists of specific ideas and solutions for each risk or hazards that have been listed down. What a warehouse action does is it helps lessen the issues so that productivity in the work environment would not be destroyed due to a hazard that is not under control. It is also used as a roadmap to find out the hazard, list them down and find a solution for the issue before it is out of control. In addition to that, a warehouse action plan can be used in a way that the answers to your problems are outlined for a more detailed and easier way to do them.

Why is it important to write out a warehouse action plan? The purpose of writing down a warehouse action plan is to help minimize or take control of the risks that go with the job. Any employer knows that anything can happen to anyone inside the workplace. That these risks if not taken care of would make the matter worse. By writing down an action plan for your warehouse job, you are making the risks lesser by being able to manage out the ones that can be managed and to plan out those that could not be. As they say it is better to be safe than sorry. So writing out a warehouse action plan just states you care about your employees enough for them to be safe from the risks that go with the job.

How to Write a Warehouse Action Plan?

Planning on writing out a warehouse action plan for your warehouse business, or just planning in case of something? What your reasons may be, there are some tips or some guidelines to help you get started. Writing out your warehouse action plan differs with just about anyone, but the important part of writing one is to be able to know how to use it and when to use it. So check out the following now.

1. Analyze and Assess the Hazards

Begin by analyzing, assessing and figuring out the following hazards that may be present in the warehouse. List all the hazards regardless if you think they can be dealt with without using an action plan. Once you have listed them all out, categorize them. They may be categorized by their severity or by the most important to the least important. That way it would be easier for you to do the second tip.

2. Evaluate the Severity of the Risks Present

Now that you have done step one, proceed to step two. Evaluate the severity of the risks present. The reason for this is to be able to understand and to gain enough knowledge of what solution fits best for this kind of risk.

3. Find a Solution for the Hazards You Listed Down

The solution for the hazards are based on the assessment and evaluation of the risk you presented and list down. Each hazard at much as possible should have at least a solution. If you think that one solution for all the hazards you have listed down is enough, at least have a second solution just in case.

4. Plan Out a Place to Assemble

This fourth tip is a requirement. This usually is for the reason if there is an accident or a physical problem that the solution you have in your action plan does not work or is not suited for the problem. A place to assemble in case of fire, earthquakes or even any kind of hazard that would befall on people.

5. Repeat and Update When Necessary

Repeat all your outlined solutions and steps when necessary. As well as to update when anything new comes up. This is especially true for the hazards in your warehouse. Whether how small or large they may be, it is always best to update to be able to find a solution for the new problem. Always better to be safe than sorry.

FAQs

What is a warehouse action plan?

An outlined document that consists of the step by step action plan that helps eliminate or lessen the risks that involve warehouse work.

Why is it necessary to have an action plan?

Action plans help out by letting the writer outline the plans they may have to solve problems. An action plan is a detailed strategy that could be used as a road map to solving problems relating to the workplace or to risks that are present in the workplace.

Are action plans fail proof?

Depending on how the action plan is made, some action plans can be considered fail proof. Especially when it has been tested out several times with great results.

Who does the warehouse action plan?

It is usually the head of the department who is responsible for writing the warehouse action plan.

Is it a requirement to update your warehouse action plan?

It is always best to have to update once in a while. As risks or hazards often come and go, it is always best to have a solution in mind.

It goes without saying, it is always better to be safe than sorry. This is true especially when you are working in a warehouse where there are a lot of risks or hazards that come with the job. To keep people safe, it is always best to write out a warehouse action plan to help lessen the problems.

Warehouse Action Plan Examples to Download to Download

Have you ever gone inside a warehouse before? If you have, you would notice there are a lot of boxes being stored side by side. You may also think of how dangerous Anyone who has ever worked in warehouses can tell you that this kind of job has its own risks and hazards. That working in a job like this that involves a lot of lifting boxes and other items would need a lot of thinking over and a lot of planning. To simply put, any kind of job that may present a lot of hazards may they be health hazards, physical hazards or that could cause pain to an employee or to someone else visiting the site is a good enough reason to plan out what should be done to avoid these kinds of problems from happening. When you plan out a way to lessen the problems that employees or anyone who may be working or visiting the warehouse, you would want to consider writing a warehouse action plan.

3+ Warehouse Action Plan Examples

1. Warehouse Action Plan Template

Details

File Format

MS Word

Google Docs

Pages

2. Warehouse Reduction Action Plan

ny.ecsgrid.com

Details

File Format

PDF

Size: 66 KB

3. Technology Warehouse Action Plan

dev-hhsconnection.hhs.texas.gov

Details

File Format

PDF

Size: 739 KB

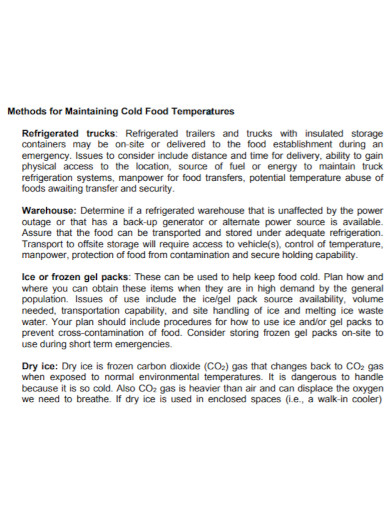

4. Standard Warehouse Action Plan

foodprotect.org

Details

File Format

PDF

Size: 771 KB

What Is a Warehouse Action Plan?

What is a warehouse action plan and what purpose does it have to write one? An action plan is a series of outlined strategies that a person follows to avoid any issues, hazards, risks or problems that go with the job. A warehouse action plan is a kind of action plan that a person composes to outline the step by step ideas or strategies that could benefit the people working in warehouses. As a lot of risks and hazards are found in a type of job such as handling warehouse items, making an action plan to avoid the problems is the most realistic solution. In addition to that, a warehouse action plan consists of specific ideas and solutions for each risk or hazards that have been listed down. What a warehouse action does is it helps lessen the issues so that productivity in the work environment would not be destroyed due to a hazard that is not under control. It is also used as a roadmap to find out the hazard, list them down and find a solution for the issue before it is out of control. In addition to that, a warehouse action plan can be used in a way that the answers to your problems are outlined for a more detailed and easier way to do them.

Why is it important to write out a warehouse action plan? The purpose of writing down a warehouse action plan is to help minimize or take control of the risks that go with the job. Any employer knows that anything can happen to anyone inside the workplace. That these risks if not taken care of would make the matter worse. By writing down an action plan for your warehouse job, you are making the risks lesser by being able to manage out the ones that can be managed and to plan out those that could not be. As they say it is better to be safe than sorry. So writing out a warehouse action plan just states you care about your employees enough for them to be safe from the risks that go with the job.

How to Write a Warehouse Action Plan?

Planning on writing out a warehouse action plan for your warehouse business, or just planning in case of something? What your reasons may be, there are some tips or some guidelines to help you get started. Writing out your warehouse action plan differs with just about anyone, but the important part of writing one is to be able to know how to use it and when to use it. So check out the following now.

1. Analyze and Assess the Hazards

Begin by analyzing, assessing and figuring out the following hazards that may be present in the warehouse. List all the hazards regardless if you think they can be dealt with without using an action plan. Once you have listed them all out, categorize them. They may be categorized by their severity or by the most important to the least important. That way it would be easier for you to do the second tip.

2. Evaluate the Severity of the Risks Present

Now that you have done step one, proceed to step two. Evaluate the severity of the risks present. The reason for this is to be able to understand and to gain enough knowledge of what solution fits best for this kind of risk.

3. Find a Solution for the Hazards You Listed Down

The solution for the hazards are based on the assessment and evaluation of the risk you presented and list down. Each hazard at much as possible should have at least a solution. If you think that one solution for all the hazards you have listed down is enough, at least have a second solution just in case.

4. Plan Out a Place to Assemble

This fourth tip is a requirement. This usually is for the reason if there is an accident or a physical problem that the solution you have in your action plan does not work or is not suited for the problem. A place to assemble in case of fire, earthquakes or even any kind of hazard that would befall on people.

5. Repeat and Update When Necessary

Repeat all your outlined solutions and steps when necessary. As well as to update when anything new comes up. This is especially true for the hazards in your warehouse. Whether how small or large they may be, it is always best to update to be able to find a solution for the new problem. Always better to be safe than sorry.

FAQs

What is a warehouse action plan?

An outlined document that consists of the step by step action plan that helps eliminate or lessen the risks that involve warehouse work.

Why is it necessary to have an action plan?

Action plans help out by letting the writer outline the plans they may have to solve problems. An action plan is a detailed strategy that could be used as a road map to solving problems relating to the workplace or to risks that are present in the workplace.

Are action plans fail proof?

Depending on how the action plan is made, some action plans can be considered fail proof. Especially when it has been tested out several times with great results.

Who does the warehouse action plan?

It is usually the head of the department who is responsible for writing the warehouse action plan.

Is it a requirement to update your warehouse action plan?

It is always best to have to update once in a while. As risks or hazards often come and go, it is always best to have a solution in mind.

It goes without saying, it is always better to be safe than sorry. This is true especially when you are working in a warehouse where there are a lot of risks or hazards that come with the job. To keep people safe, it is always best to write out a warehouse action plan to help lessen the problems.