21+ Production Plan Examples to Download to Download

People face failure. Not all entrepreneurs are capable of thriving to survive in this industry. Indeed, businesses fail. And that is the truth about it. But do you remember how all the plans that didn’t push through? If you do, then now is the time to correct mistakes from the past. Don’t take planning as anything. Whether in food, film, or media production, organizing your activities helps in achieving your goals. Take your time to prepare a production plan. Be guided in executing the right activity to achieve your goals. Create a structure and release the doubt. Increase your potential and start planning for the production today.

21+ Production Plan Examples

1. Daily Production Plan Template

2. Pre Production Plan Template

3. Film Production Plan Template

4. Production Control Plan Template

5. Production Support Plan Template

6. Web Production Plan Template

7. Production Company Business Plan Template

8. Video Production Business Plan Template

9. Production Plan Template

10. Production Deployment Plan Template

11. Video production Project Plan Template

12. Production Plan

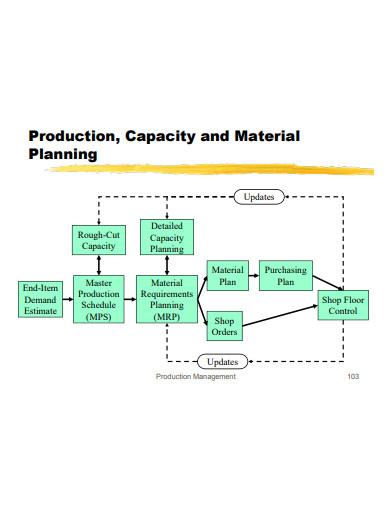

13. Production Capacity and Material Planning

14. Production Planning and Control

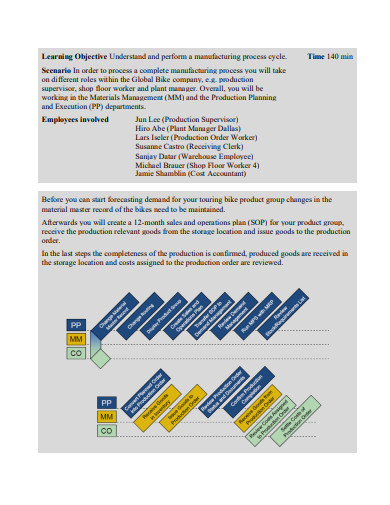

15. Production Planning and Execution

16. Sample Production Plan

17. Simple Production Plan

18. Production Line Production Plan

19. Demand Forecasting and Production Planning

20. Elements of Production Planning and Control

21. Housing Production Plan

22. Production Plan Example

What is a Production Plan?

Small businesses are always tangled with several challenges while starting a business. You can expect that there will be projects, events, and daily activities. A production plan is a detailed document that outlines the structure of the company’s operations. In the plan, there is a structure, schedule, goal, activities, and the definition of resources in between. It is one step closer to success at a time. So, whenever your path is uncertain, a production plan will help in opening the right direction. This is why entrepreneurs must consider rewriting their planning techniques. If you are having issues with the layout, the proper organization saves the day.

Business Production Situation

According to an article published by Forbes, 80% out of 100 small business owners guarantee success in the first year of business operation. It manifests an above-average rate of success. However, behind this curtain are failing attempts for smaller businesses to stand out. Generally, the business industry is at a 50% stake in reaching accomplishment and failure. Surprisingly, many companies today face a battle without enough capital. Sometimes, competition is thick and no weapon to defend. These are just among the factors that affect the whole organization. But, don’t thrive for the worst. You need a little encouragement to compete. Here, you must adjust your business activities, schedule, and operations.

Generally, you need to plan. So, before you start getting back to your daily grind, let us learn more about writing down your production plan. Follow below.

How To Create a Production Plan

If you are a manufacturing firm, it is not always easy to look into the company’s needs. There will always be lapses. And that is one thing that you should avoid. But you can do this through planning. You need your plans outlined to track the inputs of the production. That is why we help you go through it. You should understand every step by following the list below.

1. Forecast Market Demand

First things first, you need to stretch it out. To effectively plan for the future of the business, you need an estimate of the sales through market demand. How many products should you produce to meet the target demand? When should these products be released? Another way to secure this process is through current and historical information. On top of the line, there will be orders in the coming weeks. So, you need to think ahead. In general, take advantage of internal and external resources.

2. Know the Production Options Available

Here, you need to verify the tools and resources necessary to produce your products and services. Take for example, when you have a bakery business, you need to know the machines that are required to produce bread and cakes. You can start this by listing the food on the menu. Then, create a flowchart. Once these are all secured, you can already identify the resources that should be available for the business to operate. You can improve the process by having the right materials.

3. Determine the Human Resources

Aside from the equipment, you need to count how many employees you will need to operate. Of course, it is not enough to operate without the labor workers that control and monitor the production. To do this accurately, separate each team into a department. But base them according to the availability of position and equipment. Your staff should be enough to deliver and produce without delays. But aside from that, you need to weigh in your production budget. Or else, it can lead to a big commotion.

4. Monitor Plan Control

An action plan without constant monitoring is just a waste of time. Neglecting this will eventually lead to pitfalls. So, you need to measure the risk factors. This is where you compare and contrast the production process. Record a report as this helps you determine a recurring problem. Don’t let issues happen in a blink of an eye. Monitor and control while you can.

5. Make the Necessary Adjustments

For the last step, make the adjustments you intend to make with your plan. What are the challenges? Does the plan need tweaking? Production planning can be a little tricky when done wrong. Now that you have monitored and measured the risk percentage, pen down all the actions necessary. Change them according to your evaluation. Here, you should achieve a comprehensive management plan. Weigh the budget, schedule, and activities too.

FAQs

How do you define a production planning procedure?

Production planning is a process that is taken during manufacturing. It details all the necessary procedures for the company to operate. It includes hiring staff, checking the resources, evaluating the results. Through this process, the production will run smoothly.

What are the essential components of production?

Production consists of various components. These are essentials to execute the manufacturing process. This includes planning, producing, scheduling, evaluating, and following ups—all of these work hand in hand for the company to deliver quality products with no delay.

What are the primary goals of the production plan?

The general objective of production planning is to secure the workflow process of a manufacturing company. As the demand goes up, it is important to ensure that all the products released are of quality.

Are you struggling to meet your daily quota? Remember, one-day unproductive results in several risks in the business. This profoundly affects your reputation, and of course, the sales. But you can change honest mistakes. While you look at the list of tips in creating a production plan, you can resume your manufacturing business and align all the plans with your objectives. Understandably, running a business is daunting and frustrating. But you will never know your potential unless you try. So, start today. Highlight your potential by outlining all the plans necessary.