What is the primary type of deformation experienced by solids under tensile stress?

Compression

Shear

Tension

Torsion

Solid deformation refers to the alteration in the shape or size of a solid material under the influence of external forces. This process can result in changes such as stretching, compressing, bending, or twisting. Depending on the nature of the material and the magnitude of the applied forces, the deformation can be either elastic (reversible) or plastic (permanent). Hooke’s Law of Elasticity describes elastic deformation, stating that the strain in a solid material is proportional to the applied stress, as long as the material’s elastic limit is not exceeded. In contrast, Newton’s Law of Viscosity describes the flow behavior of fluids, not solids. Elastic deformation occurs when the material returns to its original shape after the removal of the force, while plastic deformation involves a permanent change in shape.

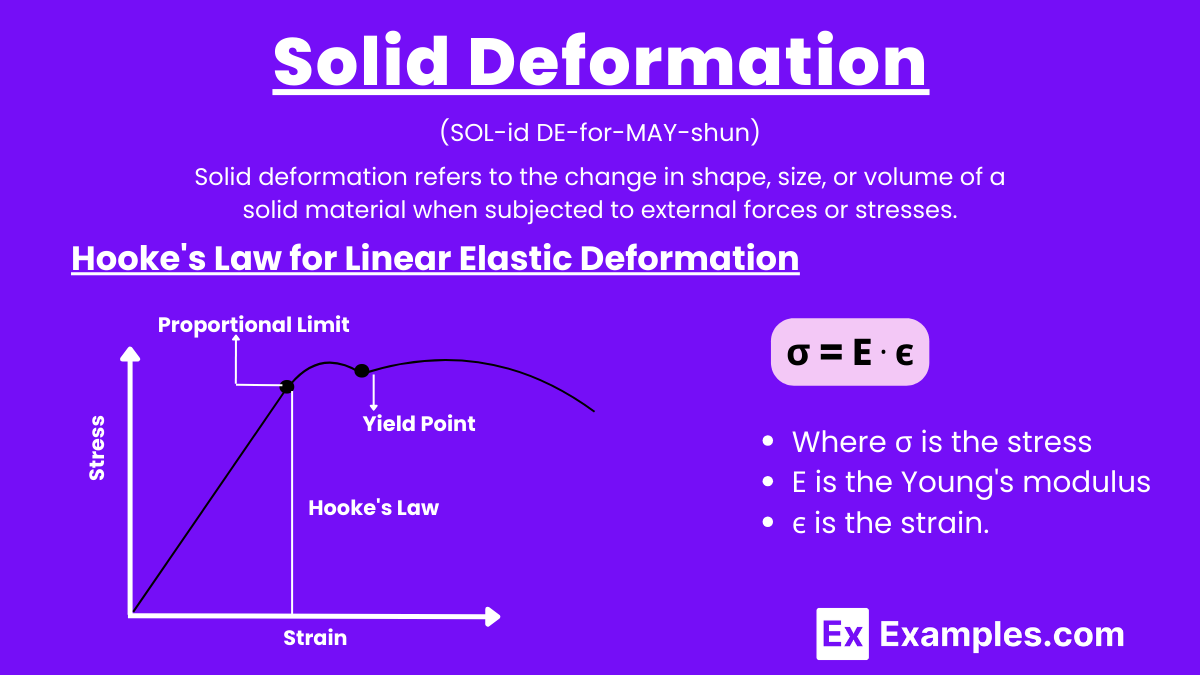

Solid deformation refers to the change in shape, size, or volume of a solid material when subjected to external forces or stresses. This deformation can be temporary, where the material returns to its original form upon the removal of the force (elastic deformation), or permanent, where the material retains its deformed shape even after the force is removed (plastic deformation).

The deformation of a solid under stress can be described using various formulas depending on the type of stress and the resulting strain. Here are some key formulas:

Where σ is the stress, E is the Young’s modulus, and ϵ is the strain.

Where K is the bulk modulus, ΔP is the change in pressure, V is the original volume, and

ΔV is the change in volume.

Where τ is the shear stress, G is the shear modulus, and γ is the shear strain.

Stress is the internal force per unit area within a material that arises from externally applied forces. It quantifies the intensity of internal forces acting within a deformable body. Stress is defined as:

Where: σ is the stress, F is the applied force, A is the cross-sectional area.

Types of Stress:

Tensile Stress: Occurs when forces act to stretch a material.

Compressive Stress: Occurs when forces act to compress a material.

Shearing Stress: Occurs when forces act parallel to the surface, causing layers to slide against each other.

Strain is the measure of deformation representing the displacement between particles in the material body relative to a reference length. It is a dimensionless quantity and is defined as:

Where: ϵ epsilonϵ is the strain. ΔL is the change in length. L is the original length.

Types of Strain:

Longitudinal Strain: Occurs when the deformation is along the length of the material. It can be tensile (stretching) or compressive (shortening).

Shear Strain: Occurs when the deformation is due to forces causing one layer to slide over another.

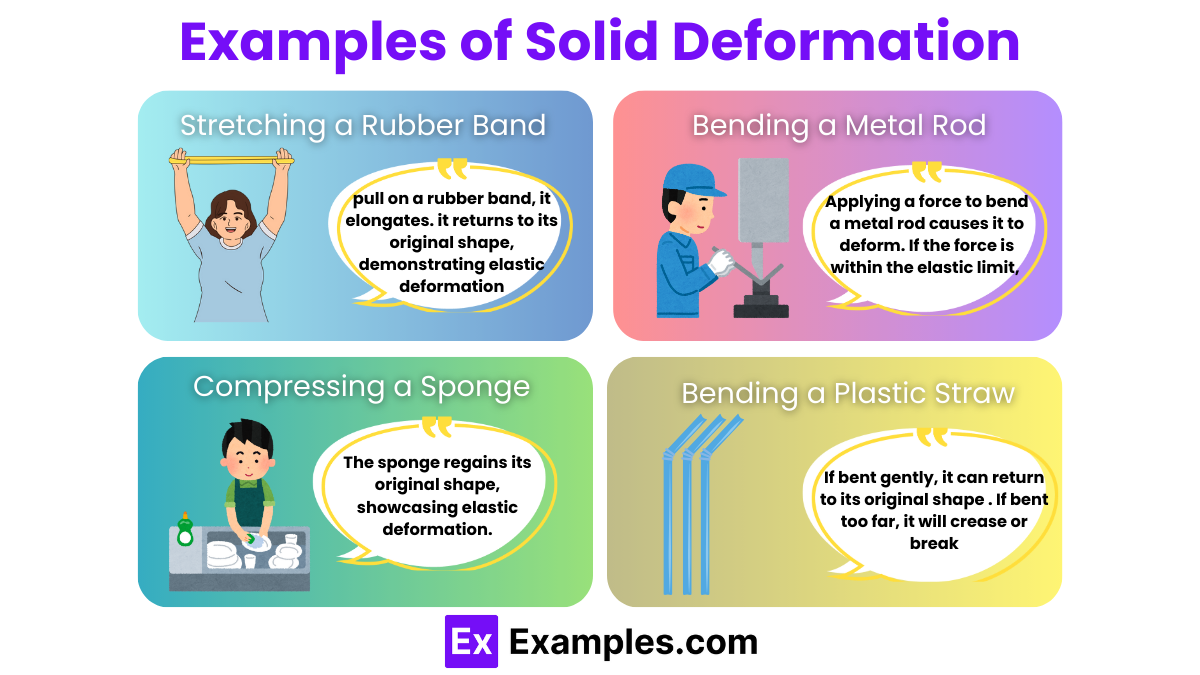

Permanent deformation, also known as plastic deformation, is the irreversible change in shape or size of a material after the applied force is removed. This type of deformation occurs when the material is stressed beyond its elastic limit, causing permanent alterations in its internal structure. Unlike elastic deformation, plastic deformation does not follow Hooke’s Law and does not revert to the original shape once the force is removed.

Characteristics:

Irreversible: The material does not return to its original shape after the removal of the force.

Permanent change in shape or size. Occurs when the material exceeds its elastic limit. For Example: Bending a metal rod permanently.

Temporary deformation, also known as elastic deformation, is the reversible change in shape or size of a material when subjected to an external force. This type of deformation occurs within the elastic limit of the material, meaning the material returns to its original shape once the force is removed. Elastic deformation follows Hooke’s Law, where the stress is directly proportional to the strain.

Characteristics:

Reversible: The material returns to its original shape after the removal of the force. Temporary change in shape or size. Occurs within the elastic limit of the material. For Example, Stretching a rubber band and having it return to its original length.

External forces such as tension, compression, and shear stress can cause solid deformation.

Hooke’s Law states that the strain in a solid is directly proportional to the applied stress within the elastic limit.

The elastic limit is the maximum stress that a material can withstand without permanent deformation.

Young’s modulus is a measure of the stiffness of a material, defined as the ratio of stress to strain in the elastic region.

Shear deformation is a change in shape caused by forces acting parallel to the surface, causing layers to slide past each other.

Tensile deformation occurs when a material is stretched, causing an increase in length.

Compressive deformation occurs when a material is compressed, leading to a decrease in length or volume.

A stress-strain curve is a graphical representation showing the relationship between stress and strain for a material under load.

Strain hardening is the process by which a material becomes stronger and more resistant to deformation through plastic deformation.

Material properties, temperature, the magnitude of the applied force, and the rate at which the force is applied all influence solid deformation.

Text prompt

Add Tone

10 Examples of Public speaking

20 Examples of Gas lighting

What is the primary type of deformation experienced by solids under tensile stress?

Compression

Shear

Tension

Torsion

Which type of stress results in a solid undergoing compression?

Shear stress

Tensile stress

Normal stress

Compressive stress

What type of deformation is caused by shear stress in solids?

Elongation

Twisting

Bending

Compression

What is the measure of a material's resistance to deformation when a force is applied?

Young's modulus

Poisson's ratio

Shear modulus

Bulk modulus

In which type of deformation do materials experience permanent changes in shape?

Elastic deformation

Plastic deformation

Viscoelastic deformation

Brittle deformation

Which type of deformation occurs when a solid is subjected to torsional forces?

Bending

Twisting

Stretching

Compression

What is the term for the limit beyond which a material will no longer return to its original shape after the removal of stress?

Elastic limit

Plastic limit

Yield point

Ultimate strength

What kind of stress is applied perpendicular to the surface of a material?

Shear stress

Tensile stress

Compressive stress

Normal stress

Which material property determines the extent to which a material can deform without breaking?

Ductility

Brittleness

Hardness

Toughness

Which type of deformation is typically observed in brittle materials when subjected to stress?

Plastic deformation

Elastic deformation

Shear deformation

Fracture

Before you leave, take our quick quiz to enhance your learning!